The global health and wellness market is experiencing an unprecedented boom, with consumers increasingly prioritizing personalized nutrition and convenient delivery formats. At the forefront of this surge is the incredibly versatile powder supplement. From high-performance protein blends and dynamic pre-workouts to nutrient-dense greens mixes and revitalizing collagen formulas, powders offer a customizable and highly effective way for individuals to optimize their daily nutrition. For burgeoning brands and established companies alike looking to innovate or expand within this thriving space, a deep and nuanced understanding of powder supplement manufacturing is absolutely essential. This intricate process involves a complex and precise interplay of scientific expertise, advanced engineering, and unwavering commitment to quality control, all designed to transform raw ingredients into a marketable, efficacious, and impeccably safe finished product that resonates with discerning consumers.

1. Raw Material Sourcing and Qualification: The Unseen Foundation

The integrity and ultimate success of any high-quality powder supplement are fundamentally built upon the purity and provenance of its raw materials. This initial, often unseen, stage is paramount for ensuring both product efficacy and consumer safety. It is where meticulous attention to detail can prevent costly issues down the line.

-

Diverse and Complex Ingredients: Powder supplements are renowned for their ability to incorporate an extraordinarily vast array of ingredients, each with unique properties and sourcing challenges. This includes:

-

Proteins: From dairy-derived (whey, casein) to an ever-expanding range of plant-based options (pea, rice, hemp, soy, pumpkin seed), each with distinct amino acid profiles and processing requirements.

-

Amino Acids: Individual amino acids or branched-chain amino acids (BCAAs), creatine, L-glutamine, and essential amino acid (EAA) blends, critical for muscle recovery and performance.

-

Vitamins & Minerals: Available in various forms (e.g., Vitamin C as ascorbic acid, magnesium as citrate or glycinate) and chelates, selected for bioavailability and stability within the powder matrix.

-

Botanicals & Extracts: Concentrated forms of herbs and plants like turmeric extract, ashwagandha, green tea extract, and elderberry, which often come with unique challenges related to purity and active compound standardization.

-

Fibers: Prebiotic fibers like inulin, FOS, or soluble corn fiber, essential for gut health, requiring careful handling due to their hygroscopic nature.

-

Sweeteners: A spectrum from bulk sweeteners like erythritol and xylitol to high-intensity options like stevia, monk fruit, and sucralose, crucial for palatability without excessive calories.

-

Flavorings & Colorings: Both natural (e.g., fruit powders, beet juice) and artificial options, carefully chosen to deliver an appealing sensory experience and enhance consumer acceptance.

-

Other Actives: Specialized ingredients such as probiotics (requiring microencapsulation for stability), digestive enzymes, adaptogens, or nootropics, each demanding precise handling.

-

-

Stringent Supplier Vetting and Due Diligence: Reputable manufacturers implement rigorous supplier qualification programs. This multi-layered process is designed to ensure that every incoming raw material meets uncompromising standards:

-

Comprehensive Auditing: This involves regular, and often unannounced, on-site inspections of supplier facilities to assess their quality management systems, hygiene protocols, and overall production capabilities. This includes reviewing their Good Agricultural Practices (GAPs) for botanicals.

-

Exhaustive Documentation Review: Manufacturers demand and meticulously verify critical documents for each batch of raw material. This includes Certificates of Analysis (CoAs), which confirm the material's identity, purity, potency, and critically, the absence of contaminants such as heavy metals (lead, arsenic, cadmium, mercury), pesticides, microbial pathogens (E. coli, Salmonella, yeast, mold), and mycotoxins. Material Safety Data Sheets (MSDS) are also reviewed.

-

Independent Third-Party Testing: Beyond supplier CoAs, a crucial step involves sending samples of incoming raw materials to independent, ISO-accredited third-party laboratories for cross-verification. This unbiased testing provides an additional layer of assurance, confirming the authenticity and purity of the ingredient before it enters the production line.

-

-

Proactive Risk Mitigation: This initial stage acts as a critical gateway for preventing significant supply chain risks. It is the frontline defense against adulteration (e.g., synthetic compounds, diluents), contamination from environmental or processing factors, and ensuring the absolute authenticity of ingredients, which are pervasive challenges in the global nutraceutical supply chain. Robust checks here prevent downstream product failures, recalls, and reputational damage.

2. Precision Blending: The Art and Science of Homogenization

Once raw materials have been rigorously qualified and approved, they move to the blending stage. This is the heart of powder supplement manufacturing, where individual components are transformed into a perfectly homogeneous, consistent mix. It's where the formulation’s scientific design is meticulously translated into a tangible product.

-

Meticulous Weighing and Batching: Each and every ingredient, no matter how small the quantity, is precisely weighed according to the product's exact formulation specifications. This step is non-negotiable for achieving accurate dosage and consistent potency in every single scoop or serving of the finished product. Advanced, highly accurate scales and often automated batching systems are employed to minimize human error and ensure reproducibility.

-

Selecting the Right Mixing Equipment: Achieving a perfectly uniform blend, especially when dealing with ingredients that have vastly different particle sizes, densities, and flow properties, requires specialized industrial blenders. The choice of blender is critical for the specific formulation:

-

V-Blenders / Double Cone Blenders: Ideal for gentle yet thorough mixing of free-flowing, granular powders, minimizing product degradation and excellent for homogeneity.

-

Ribbon Blenders: Highly effective for handling sticky, dense, or cohesive powders, and those with a wide range of particle sizes. Their ribbon design ensures robust, consistent mixing.

-

Conical Screw Blenders (Nauta mixers): Excellent for gentle, low-shear blending of fragile ingredients or large volumes, often used for very sensitive mixes.

-

High-Shear Mixers: Sometimes used for specific ingredients or to ensure complete dispersion of very fine powders.

-

-

Achieving True Homogenization: The ultimate goal of blending is to create a perfectly homogeneous blend where every single serving, from the first scoop to the last, contains the exact same ratio and concentration of active ingredients as every other scoop. This is particularly challenging when active ingredients are present in very small quantities (e.g., certain vitamins, trace minerals, or potent botanical extracts), where even slight segregation can lead to under-dosing or over-dosing.

-

In-Process Quality Control: Throughout the blending process, rigorous in-process quality checks are performed. This can involve taking multiple samples from different points within the blender at various time intervals to verify blend uniformity and ensure there's no segregation of ingredients. This proactive testing ensures consistency before moving to the next stage.

3. Granulation: Enhancing Functionality (Optional but Highly Beneficial)

For many powder formulations, particularly those with very fine powders, ingredients prone to clumping (hygroscopic), or a need for enhanced consumer experience, granulation is an optional but highly beneficial step.

-

The Granulation Process: Granulation involves the purposeful agglomeration of small, individual powder particles into larger, more uniform, and denser granules. This can be achieved through a few primary methods:

-

Wet Granulation: Involves adding a precise amount of a liquid binder (e.g., water, alcohol solution, or a binder solution) to a powder mix to form agglomerates, followed by drying the granules in fluid bed dryers or ovens. This method is effective for creating strong, consistent granules.

-

Dry Granulation (Compaction/Roller Compaction): For ingredients sensitive to moisture or heat, dry granulation is used. Powders are compressed into compacts or sheets using high pressure, which are then milled and screened into granules of a desired size. This avoids the need for solvents or drying.

-

Fluid Bed Granulation: Combines spraying, drying, and granulation in one unit, allowing for precise control over granule size and density.

-

-

Significant Benefits of Granulation:

-

Superior Flowability: Granules flow far more easily and consistently than fine powders, preventing "bridging" or "rat-holing" in hoppers and ensuring precise, efficient filling during packaging. This reduces manufacturing waste and improves production speed.

-

Reduced Segregation: By binding different ingredients together, granulation effectively prevents them from separating out during handling, transport, or storage, ensuring a uniform dose in every serving.

-

Enhanced Dissolution and Dispersibility: Granules often disperse more readily and dissolve more completely in liquids, providing a smoother, less gritty drinking experience for the consumer.

-

Minimized Dustiness: Granulated powders produce significantly less airborne dust, creating a safer and cleaner manufacturing environment and a less messy experience for the end-user.

-

Increased Bulk Density: Granulation can increase the bulk density of a powder, allowing more product to fit into a given container size, which can reduce packaging and shipping costs.

-

4. Flavoring, Coloration, and Sweetening: The Sensory Experience

While critical components are blended, the sensory attributes of the powder supplement – taste, aroma, and visual appeal – are paramount for consumer acceptance and repeat purchases. These elements are carefully managed to achieve optimal palatability and visual desirability.

-

Crafting Appealing Flavor Profiles: Achieving a delightful and consistent taste profile is perhaps one of the most challenging aspects of powder supplement manufacturing, especially for products like protein powders or greens blends that may inherently have strong or bitter notes. This involves:

-

High-Quality Flavor Systems: Using expertly developed natural or artificial flavor systems (e.g., fruit flavors, chocolate, vanilla, coffee).

-

Flavor Masking: Employing advanced techniques to effectively mask any unpleasant inherent tastes from active ingredients without compromising efficacy or adding unwanted off-notes.

-

Sensory Evaluation: Regular sensory testing by trained panels to ensure flavor consistency and consumer appeal.

-

-

Thoughtful Coloring: Colors are added not just for visual appeal but often to align with the product's flavor profile (e.g., a vibrant green for a "super greens" powder, a rich pink for a "strawberry protein"). Natural colorants derived from fruits, vegetables, or spices are increasingly preferred by consumers seeking "clean label" products.

-

Precise Sweetener Management: The choice of sweetener (nutritive sugars, sugar alcohols like erythritol, or high-intensity non-nutritive sweeteners like stevia, monk fruit, or sucralose) profoundly impacts taste, mouthfeel, and the overall caloric content of the product. Precision in blending sweeteners is vital to avoid "hot spots" of intense sweetness or areas lacking flavor. Blending different sweeteners can also achieve a more balanced and complex sweetness profile.

5. Packaging and Filling: Protecting and Presenting the Product

The final stage of powder supplement manufacturing involves accurately filling the meticulously blended and perhaps granulated powder into consumer-ready containers. This process ensures product protection, maintains integrity, and presents the brand effectively.

-

Strategic Container Selection: The choice of packaging material is crucial for product stability and consumer convenience. Common options include:

-

Plastic Tubs (HDPE, PET): Widely used for bulk powders, offering good moisture and oxygen barriers, and re-sealability.

-

Stand-Up Pouches: Flexible, lightweight, and often resealable, popular for eco-conscious brands or smaller serving sizes.

-

Flexible Sachets/Stick Packs: Ideal for single servings, promoting convenience and accurate dosing on-the-go.

-

Glass Jars: Less common for bulk powders due to weight and fragility, but sometimes used for premium, sensitive ingredients.

Considerations include moisture vapor transmission rate (MVTR), oxygen transmission rate (OTR), light protection, re-sealability, durability, and brand aesthetic.

-

-

Precision Filling Equipment: Automated filling machines are essential for accuracy and efficiency.

-

Auger Fillers: Most common for powders, using a rotating screw to dispense precise weights or volumes.

-

Volumetric Fillers: Measure by volume, suitable for free-flowing powders.

-

Gravimetric Fillers: Weigh each dose for ultimate accuracy, often used for high-value ingredients.

Accuracy is paramount during filling to ensure consistent dosage in every container, meeting label claims and consumer expectations. Overfilling is costly; underfilling can lead to regulatory issues and consumer dissatisfaction.

-

-

Robust Sealing and Tamper-Evident Features: Once filled, containers are hermetically sealed to protect the product from moisture, oxygen, and external contaminants, which are major threats to powder stability. Common sealing methods include:

-

Induction Seals: A foil liner heated to create an airtight seal to the container opening.

-

Heat Seals: For pouches and sachets.

-

Tamper-Evident Bands/Shrink Sleeves: Providing an obvious visual indicator if the product has been opened or tampered with.

These features ensure product freshness, extend shelf life, and build consumer trust.

-

-

Accurate and Compliant Labeling: Labels are precisely applied to each container, serving as the primary source of information for the consumer and regulatory bodies. The label must clearly and accurately provide:

-

Product name, brand logo, and prominent claims.

-

The legally mandated Supplement Facts panel, detailing all active ingredients, their amounts per serving, and % Daily Value.

-

A complete list of all ingredients (active and inactive).

-

Usage instructions, suggested serving size, and preparation methods.

-

All necessary warning statements (e.g., allergen declarations, "keep out of reach of children").

-

Batch number and expiration date for traceability.

-

Manufacturer or distributor information.

-

-

Final Quality Control Checks: Post-packaging, rigorous checks are performed, including:

-

Weight Verification: Automated checkweighers ensure each packaged unit meets the target weight.

-

Seal Integrity Testing: Visual and sometimes automated checks to confirm seals are airtight.

-

Visual Inspection: For label accuracy, damage, and overall aesthetic appeal.

-

Metal Detection: Final pass through metal detectors to ensure no foreign objects.

-

6. Quality Assurance and Regulatory Compliance: The Unwavering Imperative

Throughout the entirety of the powder supplement manufacturing process, from the moment raw materials enter the facility until the finished product ships, unwavering quality assurance (QA) and strict adherence to regulatory standards are non-negotiable. This comprehensive commitment is the backbone of product safety, efficacy, and brand reputation.

-

Current Good Manufacturing Practices (cGMPs): This is the bedrock of quality in supplement manufacturing. Manufacturers must rigorously follow cGMP guidelines (e.g., 21 CFR Part 111 in the U.S., or similar standards from Health Canada or EFSA). This mandates a holistic quality system covering:

-

Facility Design & Maintenance: Ensuring clean, controlled environments, proper air filtration, and preventing cross-contamination.

-

Equipment Calibration & Maintenance: Regular calibration and validation of all machinery to ensure accuracy and consistency.

-

Personnel Training: Comprehensive training for all staff on cGMPs, specific SOPs, and proper hygiene.

-

Raw Material Handling & Control: Documented procedures for receiving, quarantining, sampling, testing, and releasing raw materials.

-

In-Process Controls: Monitoring critical parameters (e.g., blend uniformity, temperature, humidity) at various production stages.

-

Packaging and Labeling Controls: Verification that correct labels are applied and packaging provides adequate protection.

-

Complaint Handling & Adverse Event Reporting: Procedures for managing customer complaints and reporting serious adverse events to regulatory bodies.

-

Meticulous Record-Keeping: Comprehensive, easily retrievable batch records, quality control reports, and deviation logs for full traceability and audit readiness.

-

-

Multi-Stage Testing and Verification:

-

In-Process Testing: Samples taken during blending and filling for real-time monitoring of uniformity, moisture content, and other critical parameters to prevent issues early.

-

Finished Product Testing: Before any batch is released, it undergoes extensive testing by in-house labs and often independent third-party laboratories for:

-

Potency: Verifying the concentration of all active ingredients against label claims, ensuring the product delivers what it promises.

-

Purity: Confirming the absence of contaminants like heavy metals, pesticides, residual solvents, and microbial pathogens.

-

Identity: Verifying that all declared ingredients are present and no undeclared substances exist.

-

Physical Characteristics: Assessing parameters like bulk density, particle size distribution, and moisture content.

-

-

-

Stability Testing and Shelf Life Determination: Products undergo rigorous real-time and accelerated stability testing under various environmental conditions (temperature, humidity). This is crucial to scientifically determine the product's shelf life and ensure that active ingredients maintain their potency and integrity until the stated expiration date. For powders, preventing caking and maintaining flowability over time is also a key stability concern.

-

Proactive Regulatory Compliance: Beyond cGMPs, manufacturers must have dedicated regulatory affairs teams or consultants who stay abreast of continually evolving national and international regulations. This includes:

-

Label and Claim Review: Rigorous review of all product labels, marketing materials, and advertising claims to ensure they are fully compliant, truthful, and not misleading (e.g., distinguishing between structure/function claims and prohibited disease claims).

-

Ingredient Permissibility: Verifying that all ingredients are approved for use in dietary supplements in the target markets and conform to any specific purity standards or restrictions.

-

Export/Import Regulations: Navigating complex customs and trade regulations if products are destined for international markets.

-

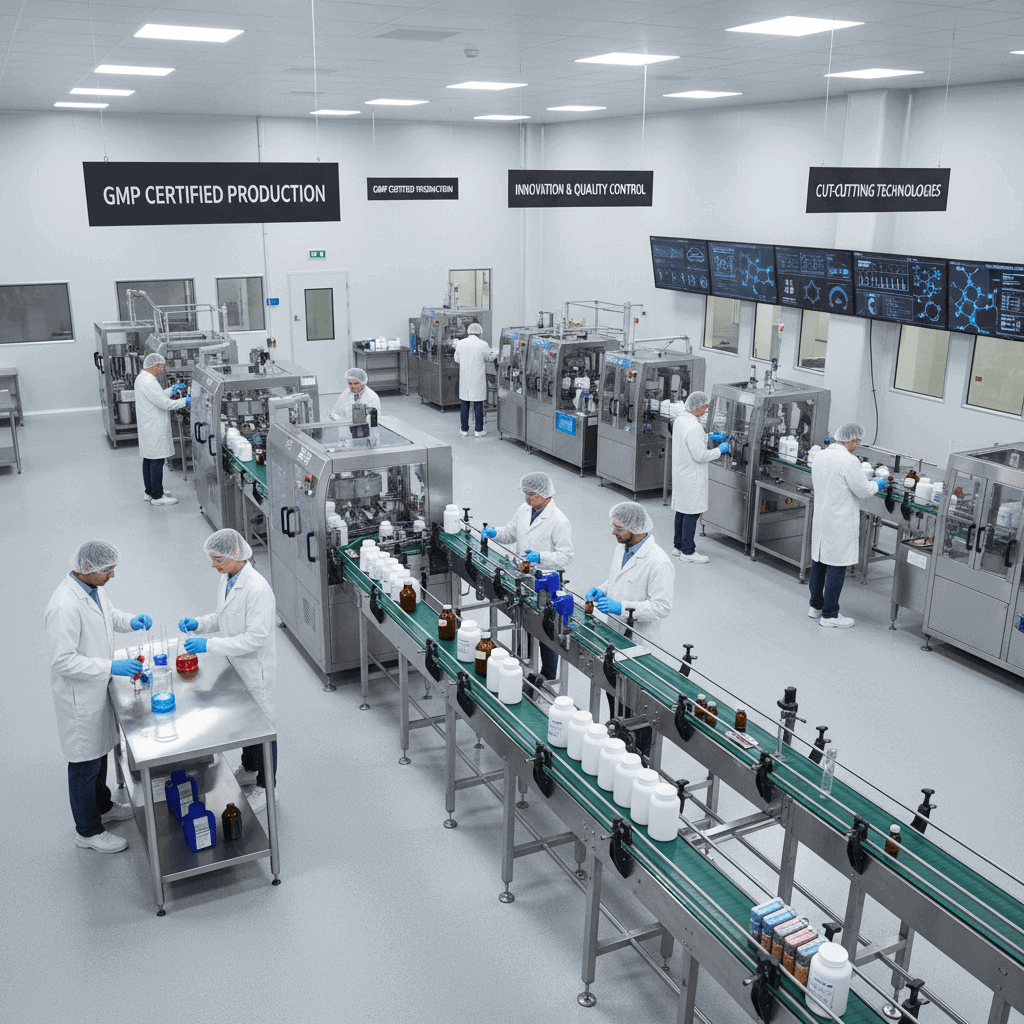

Why Partner with a Specialized Powder Supplement Manufacturer?

For brands aiming to succeed in the competitive powder supplement market, collaborating with a specialized, cGMP-compliant manufacturer is not just an advantage—it's a necessity.

-

Unrivaled Expertise and Experience: Dedicated powder manufacturers possess profound knowledge of blending science, intricate ingredient compatibility, and the specific challenges inherent to powders, such as moisture sensitivity, particle size distribution, and ingredient segregation. They understand how to stabilize sensitive actives and optimize sensory properties.

-

Access to Specialized Equipment: These manufacturers have invested heavily in cutting-edge, industrial-grade blending, granulation, and high-speed filling equipment specifically optimized for powder production. This ensures precision, efficiency, and scalability that would be prohibitively expensive for most brands to acquire independently.

-

Built-in cGMP Compliance and Robust Quality Systems: Established manufacturers already operate in cGMP-compliant facilities with stringent quality control protocols ingrained into every step of their process. This significantly de-risks your launch by ensuring your product meets the highest standards for safety, purity, and potency from day one, avoiding costly regulatory hurdles.

-

Scalability for Growth: Whether you're planning a small initial run to test the market or anticipate large-volume orders as your brand expands, a specialized manufacturer possesses the capacity and flexibility to scale production efficiently without compromising quality or lead times.

-

Optimized Cost Efficiency: By leveraging a manufacturer's existing infrastructure, their bulk purchasing power for raw materials, and their optimized operational efficiencies, partnering can be significantly more cost-effective than attempting to set up your own manufacturing facility. This frees up your capital for marketing and brand development.

-

Invaluable Regulatory Guidance: Reputable manufacturers provide crucial guidance on complex regulatory requirements, proper labeling (including the critical Supplement Facts panel), and acceptable claims, ensuring your product is fully compliant across all target markets. They act as your shield against potential legal and regulatory pitfalls.

Powder supplement manufacturing is a sophisticated, multi-stage process that demands precision, specialized expertise, and an unwavering commitment to quality at every single juncture. From the meticulous selection and rigorous testing of raw materials to the art of achieving a perfectly homogeneous blend, the optional benefits of granulation, and the precise, protective packaging, every step is critical to the integrity and market success of the final product. For brands looking to make their mark in the dynamic health and wellness sector, understanding these intricate processes and, crucially, partnering with a knowledgeable, cGMP-compliant, and experienced manufacturer is the undeniable key to producing safe, effective, and highly marketable powder supplements that truly resonate with the evolving demands of today's health-conscious consumers.

Partner with Zhongci Health for Your Powder Supplement Success

Ready to bring your vision for the next market-leading powder supplement to life? Zhongci Health is your trusted partner for high-quality powder supplement manufacturing. We combine advanced technology, rigorous cGMP compliance, and deep expertise in blending and formulation to deliver exceptional products. Whether you're launching a new protein, a greens blend, or a specialized nutritional powder, we streamline your journey from concept to consumer, ensuring product integrity and market readiness. Focus on your brand; we'll handle the manufacturing precision.