In the highly competitive and rapidly evolving nutritional supplement industry, adhering to Good Manufacturing Practices (GMP) is the non-negotiable baseline. While GMP ensures fundamental quality standards, for brands aiming to build trust, differentiate themselves, and truly guarantee product purity, potency, and safety, a commitment to quality must extend far "beyond GMP." This involves implementing sophisticated Quality Assurance (QA) systems and leveraging cutting-edge analytical testing methodologies throughout the entire product lifecycle—from raw material sourcing to post-market surveillance.

Consumers are increasingly discerning, demanding not just efficacy but also transparency and verifiable proof of quality. Regulatory bodies are also becoming more stringent, with global markets presenting a mosaic of complex requirements. For manufacturers and brands alike, merely meeting minimum compliance is no longer sufficient to thrive. This comprehensive guide will delve into the advanced strategies and technologies employed in modern supplement manufacturing to elevate quality beyond standard expectations, ensuring every product delivers on its promise.

1. The Foundation: Revisiting GMP as the Baseline

Before exploring advanced practices, it's essential to briefly acknowledge the foundational role of GMP. GMP regulations (e.g., FDA 21 CFR Part 111 in the US, EU GMP guidelines for food supplements, TGA's GMP in Australia) establish minimum requirements for methods, facilities, and controls used in manufacturing, packaging, labeling, or holding dietary supplements.

Key aspects of GMP include:

-

Quality Management System:Procedures, processes, and responsibilities.

-

Personnel:Qualified and trained staff.

-

Premises & Equipment:Suitable design, maintenance, and calibration.

-

Documentation:Comprehensive records of all processes.

-

Production & Process Controls:Validated manufacturing procedures.

-

Testing:Raw material, in-process, and finished product testing.

-

Complaint Handling:Procedures for addressing customer feedback.

-

Recalls:Mechanisms for product withdrawal.

While crucial, GMP sets a bar that many leading manufacturers aim to surpass.

2. Advanced Quality Assurance Systems: Building a Culture of Excellence

Moving "beyond GMP" involves integrating a holistic approach to quality that permeates every aspect of the organization.

2.1 Total Quality Management (TQM) Principles:

TQM is a management philosophy that emphasizes continuous improvement, customer satisfaction, and employee involvement in quality. In supplement manufacturing, TQM means:

-

Customer Focus:Understanding and exceeding consumer expectations for product quality, safety, and efficacy.

-

Leadership Commitment:Management actively driving and supporting quality initiatives.

-

Employee Engagement:Empowering all staff to take ownership of quality processes.

-

Process Approach:Viewing all activities as interconnected processes to be optimized.

-

Continuous Improvement (Kaizen):Regularly assessing and enhancing every aspect of operations.

-

Fact-Based Decision Making:Relying on data from rigorous testing and monitoring.

-

Supplier Relationship Management:Building strong, collaborative relationships with trusted raw material suppliers.

2.2 Implementing a Robust Quality Management System (QMS):

A QMS is a formalized system that documents processes, procedures, and responsibilities for achieving quality policies and objectives. Beyond basic GMP documentation, advanced QMS may incorporate:

-

ISO 9001 Certification:An international standard for quality management systems, indicating a commitment to continuous improvement and customer satisfaction.

-

Risk-Based Approach to QA:Proactively identifying, assessing, and mitigating potential quality risks at every stage, from ingredient sourcing to product distribution. This includes Hazard Analysis and Critical Control Points (HACCP) principles, but extended across the entire quality lifecycle.

-

Digital QMS Solutions:Utilizing software platforms to manage documents, training records, deviations, CAPA (Corrective and Preventive Actions), audits, and change controls, enhancing efficiency and data integrity.

-

Internal Audit Programs:Regular, rigorous internal audits to assess compliance, identify areas for improvement, and prepare for external inspections.

2.3 Comprehensive Vendor Qualification Programs:

The quality of the final product begins with the quality of raw materials. Advanced QA implements stringent vendor qualification:

-

Multi-Tiered Vetting:Beyond basic documentation, this involves on-site audits of suppliers, assessment of their quality systems, and review of their raw material testing capabilities.

-

Certificate of Analysis (CoA) Verification:Not just accepting CoAs, but actively verifying their contents through independent third-party testing of incoming raw material batches.

-

Supplier Performance Monitoring:Ongoing evaluation of supplier quality, delivery, and responsiveness.

-

Ethical and Sustainable Sourcing Audits:Ensuring suppliers adhere to ethical labor practices and environmental sustainability standards, increasingly important for global markets.

3. Cutting-Edge Analytical Testing Methods: Ensuring Purity, Potency, and Safety

Analytical testing is the backbone of quality assurance, providing quantifiable data to confirm product specifications. Moving "beyond GMP" means employing a broader range of advanced techniques.

3.1 Raw Material Testing (Comprehensive Intake Analysis):

Every incoming batch of raw material undergoes rigorous testing before release for production.

-

Identity Testing:Confirming the raw material is what it claims to be.

-

FTIR (Fourier-Transform Infrared Spectroscopy):Rapid identification of compounds based on their unique molecular "fingerprint."

-

NIR (Near-Infrared Spectroscopy):Quick, non-destructive method for identity and basic quantitative analysis.

-

HPLC (High-Performance Liquid Chromatography):Separates and identifies components in a mixture, often used for botanicals and vitamins.

-

-

Purity Testing:Ensuring the absence of contaminants.

-

Heavy Metals (e.g., Lead, Mercury, Cadmium, Arsenic):

-

ICP-MS (Inductively Coupled Plasma Mass Spectrometry):Highly sensitive for ultra-trace metal detection.

-

-

Pesticides & Herbicides:

-

GC-MS (Gas Chromatography-Mass Spectrometry):Separates and identifies volatile and semi-volatile organic compounds.

-

LC-MS (Liquid Chromatography-Mass Spectrometry):For non-volatile compounds.

-

-

Solvent Residues:GC-MS for residual solvents from extraction processes.

-

Mycotoxins:HPLC or ELISA methods for fungal toxins (e.g., aflatoxins).

-

-

Potency Testing:Quantifying the active ingredient content.

-

HPLC, GC, UV-Vis Spectroscopy:Depending on the specific active compound.

-

Microbiological Testing:Assessing microbial load (total plate count, yeasts, molds) and absence of specific pathogens (E. coli, Salmonella, Staphylococcus aureus) using traditional culture methods or rapid PCR-based tests.

-

3.2 In-Process Testing:

Regular checks during manufacturing to ensure consistency and prevent deviations.

-

Weight Uniformity:For capsules/tablets.

-

Disintegration/Dissolution:Ensuring tablets/capsules break down and release active ingredients correctly.

-

pH, Viscosity:For liquid formulations.

-

Environmental Monitoring:Air quality, surface cleanliness in cleanrooms.

3.3 Finished Product Testing:

Final verification of the completed product before release.

-

Identity, Purity, Potency:Re-testing to confirm final product meets specifications and label claims.

-

Microbiological Testing:Confirming no contamination during manufacturing/packaging.

-

Stability Testing:

-

Real-time Stability:Products stored at recommended conditions over time to determine actual shelf-life.

-

Accelerated Stability:Products stored at elevated temperatures/humidity to predict shelf-life more quickly. This data is critical for determining "Best Before" dates and ensuring potency retention.

-

-

Allergen Testing:Specific ELISA-based tests to confirm absence or presence of major allergens if applicable.

3.4 Specialized Testing:

-

Heavy Metals and Contaminants beyond basic requirements:Testing for emerging contaminants or those relevant to specific geographical sourcing.

-

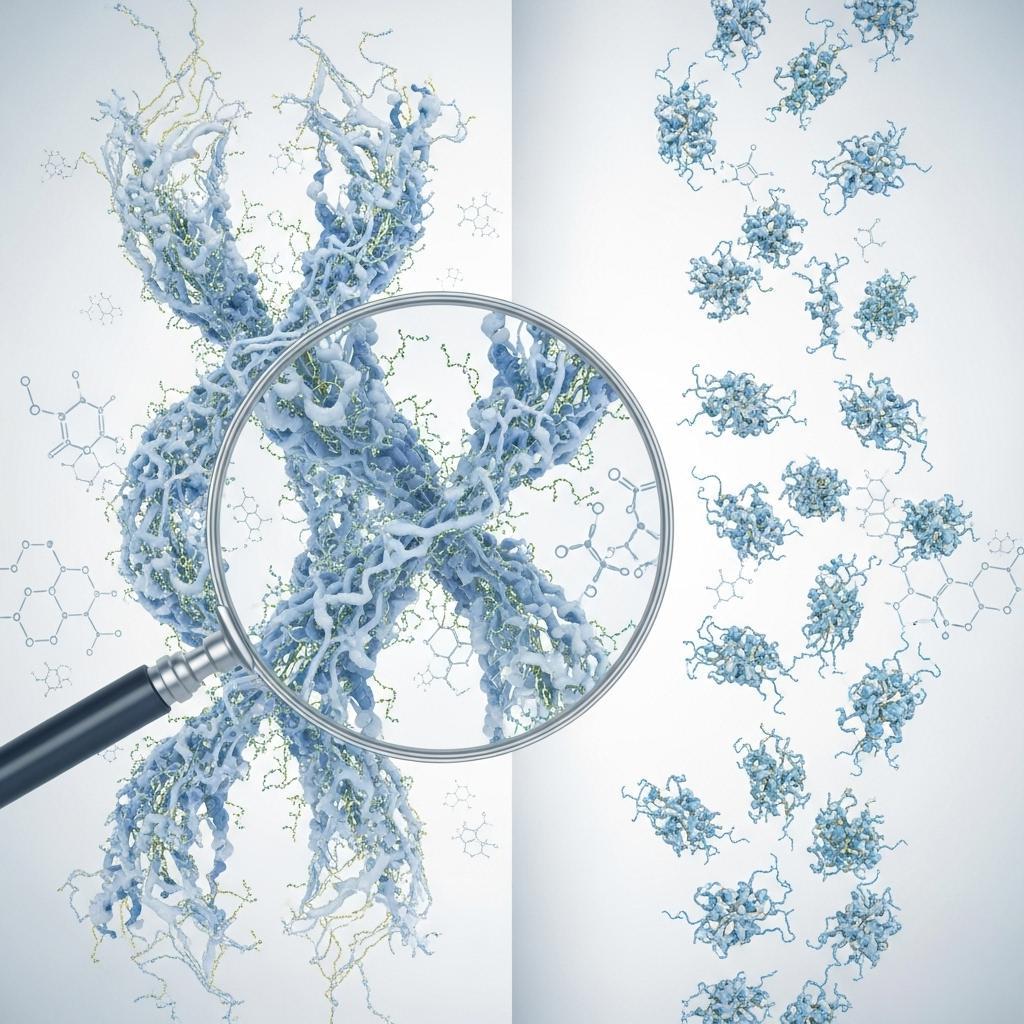

DNA Barcoding (for botanicals):Verifying the authenticity of plant-based ingredients at a genetic level to prevent adulteration.

-

Peroxide Value/Anisidine Value:For Omega-3 oils to check oxidation status.

-

Sporting Banned Substances:Testing by third parties like Informed-Sport or NSF Certified for Sport to ensure products are free from WADA-prohibited substances, critical for athlete-focused brands.

4. Third-Party Verification and Certifications: The Credibility Imperative

While in-house testing is vital, independent third-party verification provides an unbiased layer of assurance and builds immense consumer trust.

4.1 ISO 17025 Accreditation for Testing Labs:

-

Significance:This is the highest international standard for the competence of testing and calibration laboratories. It indicates that the lab operates a robust quality management system and is technically competent to produce precise and accurate test results.

-

Benefit:Brands should prioritize manufacturers that use or partner with ISO 17025 accredited labs for their critical testing, especially for potency and contaminant screening.

4.2 Product-Specific Certifications:

-

NSF International:Offers various certifications (e.g., Dietary Supplements, Certified for Sport) which involve product testing, facility audits, and label claim verification.

-

USP (U.S. Pharmacopeia):Offers a Dietary Supplement Verification Program, testing products for potency, purity, dissolution, and adherence to GMP.

-

Informed-Sport/Informed-Choice:Global testing programs for sports nutrition products, certifying they are free of banned substances.

-

BRCGS Global Standards / FSSC 22000:Food safety management systems that go beyond basic GMP, often preferred by retailers globally.

-

Organic Certifications (e.g., USDA Organic, EU Organic Logo):Requires adherence to specific organic farming and processing standards.

-

Non-GMO Project Verified:Certifies products are free of genetically modified organisms.

-

Vegan/Vegetarian Society Trademarks:For plant-based products.

4.3 Audit Readiness and Transparency:

-

Leading manufacturers maintain continuous audit readiness, welcoming inspections from regulatory bodies, third-party certifiers, and even direct brand client audits.

-

Transparency in sharing audit reports, Certificates of Analysis, and detailed process documentation fosters strong client relationships.

5. Traceability and Supply Chain Integrity: From Source to Shelf

Advanced QA extends beyond the factory walls to encompass the entire supply chain, ensuring integrity and visibility.

5.1 "Farm-to-Fork" / "Source-to-Shelf" Traceability:

-

Concept:The ability to track every raw material and finished product batch forward and backward through the entire supply chain.

-

Implementation:Robust internal systems (e.g., ERP software, LIMS) linked with supplier data.

-

Benefits:Crucial for rapid recalls, identifying contamination sources, and verifying ethical/sustainable sourcing claims.

5.2 Blockchain Technology in Supply Chain:

-

Potential:Offers a decentralized, immutable, and transparent ledger for recording every transaction and movement of ingredients and products.

-

Application:Can enhance trust in ingredient origin, verify certifications, and provide consumers with unprecedented transparency via QR codes on packaging.

5.3 Proactive Supplier Qualification:

-

Beyond initial vetting, continuous monitoring of supplier performance, quality, and adherence to sustainability/ethical standards.

-

Regular re-qualification audits and risk assessments.

6. Post-Market Surveillance and Continuous Improvement

Quality assurance doesn't end when the product leaves the factory; it extends into the market and loops back into continuous improvement.

6.1 Adverse Event Reporting and Complaint Handling:

-

Robust Systems:Efficient systems for receiving, documenting, investigating, and reporting adverse events or product complaints from consumers.

-

Root Cause Analysis:Thorough investigation to identify the underlying cause of any issues.

-

Regulatory Reporting:Adhering to mandatory reporting requirements for adverse events to relevant health authorities (e.g., FDA, Health Canada, TGA).

6.2 CAPA (Corrective and Preventive Actions):

-

Systematic Approach:Implementing formal CAPA processes to address identified deviations, non-conformances, or complaints.

-

Corrective Action:Eliminating the cause of an existing non-conformity.

-

Preventive Action:Eliminating the cause of a potential non-conformity.

-

Effectiveness Checks:Verifying that implemented CAPAs are effective in preventing recurrence.

6.3 Continuous Process Improvement:

-

Data Analysis:Utilizing data from QA metrics, testing results, complaints, and audits to identify trends and areas for optimization.

-

Lean Manufacturing & Six Sigma Principles:Applying methodologies to reduce waste, improve efficiency, and minimize defects in manufacturing processes.

-

Regular Management Review:Periodic reviews of the QMS by top management to ensure its continued suitability, adequacy, and effectiveness.

7. The Role of Technology in Advanced QA

Modern technology is a cornerstone of advanced quality assurance.

-

LIMS (Laboratory Information Management Systems):Manages lab samples, tests, results, and data, integrating with instruments for efficiency and data integrity.

-

ERP (Enterprise Resource Planning) Systems:Integrates all aspects of manufacturing, supply chain, and quality management, providing holistic data visibility.

-

Automated Testing Equipment:Reduces human error and increases throughput for repetitive testing.

-

Artificial Intelligence (AI) and Machine Learning (ML):

-

Predictive Analytics:Forecasting potential quality issues based on historical data.

-

Real-time Monitoring:AI-powered sensors on production lines detecting deviations instantaneously.

-

Data Analysis:ML algorithms identifying subtle patterns in vast amounts of quality control data.

-

-

IoT (Internet of Things) Sensors:For real-time environmental monitoring (temperature, humidity) in storage and production areas.

Conclusion

In an industry where consumer trust is paramount, moving "beyond GMP" is no longer an aspiration but a strategic imperative. Advanced Quality Assurance and rigorous analytical testing are the pillars upon which brands can build a reputation for uncompromising quality, safety, and efficacy. By investing in sophisticated QMS, employing cutting-edge testing methodologies, embracing third-party verification, ensuring robust traceability, and committing to continuous improvement, manufacturers can offer unparalleled confidence in their products.

For brands, partnering with a manufacturer that champions these advanced QA principles means far more than just compliance; it means securing a competitive advantage, fostering enduring consumer loyalty, and ensuring your products consistently deliver the health benefits they promise, paving the way for sustainable global growth.

Zhongci Health: Your Partner in Uncompromising Quality

AtZhongci Health, we understand that true quality extends far beyond basic GMP. We are committed to an advanced Quality Assurance philosophy, integrating cutting-edge analytical testing, robust supply chain traceability, and continuous improvement across all our manufacturing processes. Our state-of-the-art laboratories, ISO 17025 accredited partnerships, and dedicated QA teams ensure every batch of your private label supplements meets the most stringent international standards for purity, potency, and safety. Partner withZhongci Healthto provide your consumers with products they can implicitly trust, cementing your brand's reputation for uncompromising excellence in a competitive global market. Contact us today to learn how our advanced QA can elevate your brand.