In the vast and ever-growing market for dietary supplements, consumers often focus on ingredients, benefits, and brand reputation. However, a less obvious yet equally critical factor influencing a supplement's quality, efficacy, and safety is its manufacturing date. This seemingly simple piece of information, often found alongside an expiration or "best by" date, marks the beginning of a supplement's lifecycle and directly impacts its journey from production to potential degradation. Understanding the significance of this date is crucial for both consumers seeking effective products and brands committed to delivering on their promises.

This comprehensive guide will explore how the manufacturing date affects various types of dietary supplements, delve into the regulatory standards governing these dates, and highlight why awareness of this information is vital for maintaining product integrity and consumer confidence.

The Silent Countdown: Why Manufacturing Date Matters

The manufacturing date is the moment a supplement officially comes into existence. From this point forward, the clock starts ticking on its stability, potency, and overall quality. Various factors begin to influence the product's integrity:

1. Nutrient Degradation and Potency Loss

Not all ingredients are created equal in terms of stability. Many vitamins, minerals, and other bioactive compounds are susceptible to degradation over time due to exposure to light, heat, air, and moisture.

-

Vitamins:

-

Water-soluble vitamins (e.g., Vitamin C, B vitamins): These are particularly fragile. Vitamin C (ascorbic acid) can degrade rapidly when exposed to heat, light, or oxygen. Similarly, some B vitamins, like Folic Acid and Thiamine (B1), are highly sensitive. A product manufactured long ago, even if stored correctly, may have significantly less active Vitamin C than stated on the label by the time it's consumed.

-

Fat-soluble vitamins (e.g., Vitamins A, D, E, K): While generally more stable than water-soluble vitamins, they can still degrade over prolonged periods or under adverse storage conditions. Vitamin A is sensitive to oxidation, and Vitamin E, despite being an antioxidant, can also break down.

-

-

Minerals: Generally very stable, but their bioavailability can sometimes be affected by interactions with other degrading compounds over time, or by changes in the supplement matrix.

-

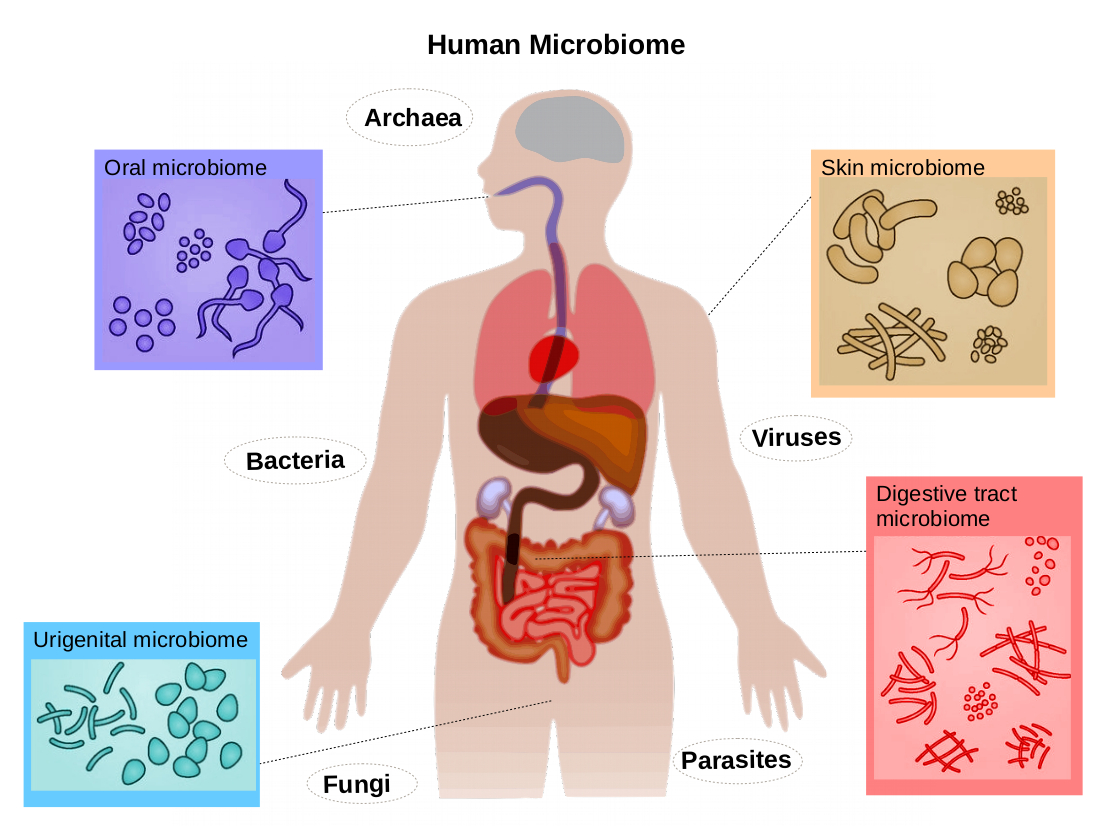

Probiotics: These are living microorganisms, making them exceptionally sensitive to temperature, moisture, and even oxygen. Their viability—the number of live colony-forming units (CFUs)—decreases significantly over time. A probiotic supplement's potency is directly tied to its manufacturing date and storage conditions.

-

Enzymes: Like probiotics, digestive enzymes are biological molecules that can lose their activity (measured in specific enzyme units) over time, especially if exposed to unfavorable conditions.

-

Herbal Extracts and Botanicals: The active compounds in many herbal ingredients (e.g., curcuminoids in turmeric, polyphenols in green tea extract) can degrade, losing their therapeutic efficacy. The complex chemical profiles of botanicals make their stability prediction intricate.

-

Omega-3 Fatty Acids: Highly susceptible to oxidation (rancidity) when exposed to air, light, or heat. Oxidized omega-3s can develop an unpleasant odor/taste and may lose their beneficial properties, potentially even forming harmful compounds. The manufacturing date is critical here, as rancidity is a time-dependent process.

-

Amino Acids and Proteins: Generally stable, but protein powders can undergo changes in texture or solubility over very long periods, especially if exposed to moisture.

2. Purity and Safety Concerns

Beyond potency loss, time can also introduce purity and safety issues.

-

Moisture Absorption: If packaging is compromised or the product is stored in humid conditions, supplements can absorb moisture. This can lead to clumping (powders), softening (tablets), and, critically, create an environment conducive to microbial growth (mold, bacteria) or accelerate chemical degradation reactions.

-

Chemical Interactions: Over extended periods, even well-formulated supplements can experience subtle chemical reactions between ingredients, potentially leading to the formation of undesirable by-products or changes in the product's physical characteristics (e.g., color changes, altered taste).

-

Microbial Growth: While most supplements are manufactured under strict sanitary conditions, the potential for microbial proliferation increases if product integrity (e.g., moisture barrier) is compromised over time. This is a particular concern for liquid supplements or probiotics.

3. Organoleptic Changes

The manufacturing date also influences the sensory attributes of a supplement.

-

Taste and Odor: Flavored powders, gummies, and liquid supplements can lose their intended flavor or develop off-tastes/odors as active compounds degrade or ingredients interact. Omega-3s turning rancid is a prime example.

-

Texture and Appearance: Powders can clump, tablets can crumble or change color, and softgels can become sticky or brittle. These changes, while sometimes harmless, signal degradation and can negatively impact consumer perception and compliance.

Understanding Regulatory Standards: Manufacturing Date vs. Expiration Date

It's essential to differentiate between the manufacturing date and the expiration date (or "best by" date). While the manufacturing date marks when the product was made, the expiration or "best by" date is the more critical indicator for consumers.

Regulatory Frameworks (U.S. Focus - FDA)

In the United States, the Food and Drug Administration (FDA) regulates dietary supplements under the Dietary Supplement Health and Education Act of 1994 (DSHEA). Unlike drugs, dietary supplements do not require pre-market approval from the FDA. However, manufacturers are subject to Current Good Manufacturing Practices (cGMPs) for dietary supplements (21 CFR Part 111).

-

cGMPs and Stability Testing: Under cGMPs, manufacturers are required to establish and follow quality control procedures to ensure that supplements meet quality standards. A critical part of this is stability testing. Manufacturers must conduct scientific studies to determine the product's shelf life and verify that it maintains its identity, purity, strength, and composition throughout its declared shelf life.

-

Expiration Date Requirement:

-

The FDA does not strictly require an expiration date on dietary supplement labels.

-

However, if a manufacturer chooses to include an expiration date (or a "best by," "use by," or "sell by" date), they must have scientific data to support that date. This means they must prove the product will meet its label claims for potency and purity up to that date, assuming proper storage.

-

Most reputable manufacturers do include an expiration date because it provides critical information to consumers and demonstrates commitment to quality.

-

-

Manufacturing Date Requirement: The FDA cGMPs require manufacturers to establish a batch production record for each batch of dietary supplement produced. This record must include the date of manufacture. While the manufacturing date itself isn't always prominently displayed on the final product label for consumers, it is an internal record critical for traceability and quality control. Some manufacturers choose to include it as part of the lot number or in a separate date code.

International Regulations

Other regions have similar but varying requirements:

-

European Union (EU): EU regulations often require a "best before" date for food supplements, signifying when the product retains its specific properties when properly stored.

-

Canada (Health Canada): Health Canada generally requires an expiry date for natural health products (NHPs), which encompasses most dietary supplements.

-

Australia (TGA): The Therapeutic Goods Administration (TGA) also has specific requirements for expiry dates and stability data for listed and registered complementary medicines.

Regardless of specific labeling requirements, the underlying principle is universal: manufacturers must have scientific data to back up any claims about product longevity and potency.

The Link: Manufacturing Date, Shelf Life, and Storage Conditions

The manufacturing date, combined with the product's formulation and packaging, dictates its shelf life. The expiration date is the end point of this shelf life, validated by stability studies.

-

Impact of Formulation: The inherent stability of ingredients (e.g., probiotics vs. minerals), the presence of protective excipients (e.g., antioxidants, desiccants), and the specific delivery form (e.g., encapsulated vs. liquid) all influence how quickly a product degrades from its manufacturing date.

-

Packaging: Protective packaging (e.g., amber glass bottles for light protection, blister packs for moisture control, nitrogen-flushed containers for oxygen sensitive ingredients) plays a crucial role in extending shelf life from the manufacturing date by minimizing exposure to degradative factors.

-

Storage Conditions: How a product is stored after manufacturing and before consumption is paramount. High heat, direct sunlight, and humidity can drastically accelerate degradation, rendering a product ineffective or even unsafe long before its stated expiration date. For instance, a probiotic supplement manufactured 6 months ago might be perfectly potent if refrigerated, but largely ineffective if left in a hot car.

What Brands Need to Know (and Communicate)

For dietary supplement brands, understanding the manufacturing date's implications is vital for brand integrity.

-

Prioritize Stability Testing: Work with manufacturers who conduct robust, real-time stability testing beyond just accelerated studies. This ensures accurate shelf-life claims.

-

Choose Stable Formulations and Packaging: Select ingredient forms and packaging materials that offer maximum protection against degradation factors relevant to your product.

-

Educate Consumers on Storage: Clearly communicate optimal storage conditions on your labels and marketing materials (e.g., "Store in a cool, dry place," "Refrigerate after opening"). This empowers consumers to preserve product quality from the manufacturing date through consumption.

-

Monitor Your Supply Chain: Be aware of how long products are held in distribution channels post-manufacturing. Longer transit or warehouse times reduce the effective shelf life available to the consumer.

-

Quality Assurance Beyond the Date: Emphasize that the expiration date is a promise. Brands must ensure their manufacturers have stringent cGMPs to guarantee that promise holds true.

What Consumers Need to Know

For consumers, being aware of the manufacturing date (if provided) and understanding its relationship with the expiration date helps in making informed decisions.

-

Check Expiration Dates: Always prioritize checking the expiration or "best by" date before purchasing and consuming any supplement. Do not use supplements past this date.

-

Consider Manufacturing Date for Sensitive Products: For highly sensitive supplements like probiotics or omega-3s, a manufacturing date closer to your purchase date generally means higher initial potency, assuming proper storage.

-

Store Correctly: Follow the storage instructions on the label meticulously. Proper storage is key to ensuring the product remains effective up to its expiration date.

-

Buy from Reputable Sources: Purchase supplements from trusted retailers or directly from brands with transparent quality practices. This reduces the risk of buying expired or improperly stored products.

Conclusion

The manufacturing date isn't just a number on a label; it's the starting point of a supplement's journey, directly influencing its potency, purity, and shelf life. From the inherent instability of certain vitamins and sensitive probiotics to the crucial role of packaging and storage, every element plays a part in a product's integrity over time. For dietary supplement brands, a deep commitment to rigorous stability testing, cGMP compliance, and clear consumer communication is paramount to standing by their products' efficacy and safety. For consumers, understanding this silent clock empowers them to make smarter choices, ensuring the supplements they invest in deliver the health benefits they expect, every time.

Authoritative Sources and References

- U.S. Food and Drug Administration (FDA) - Dietary Supplements. Retrieved from https://www.fda.gov/food/dietary-supplements

- FDA - Current Good Manufacturing Practice (cGMP) Regulations for Dietary Supplements (21 CFR Part 111). Retrieved from https://www.fda.gov/food/dietary-supplements-guidance-documents-regulatory-information/current-good-manufacturing-practice-cgmp-regulations

- U.S. Pharmacopeia (USP). Standards for Identity, Strength, Quality, and Purity of Medicines and Food Ingredients. Retrieved from https://www.usp.org/

- National Institutes of Health (NIH) - Office of Dietary Supplements (ODS). Science-Based Supplement Information. Retrieved from https://ods.od.nih.gov/

- Council for Responsible Nutrition (CRN). Quality and Regulatory Compliance Resources. Retrieved from https://www.crnusa.org/

- Health Canada - Natural Health Products (NHPs). Regulatory Information Including Expiry Date Requirements. Retrieved from https://www.canada.ca/en/health-canada/services/drugs-health-products/natural-health-products.html

- European Food Safety Authority (EFSA). Scientific Advice and Risk Communication on Food Supplements. Retrieved from https://www.efsa.europa.eu/

Note: Always consult the latest official guidelines from the relevant regulatory bodies in your specific region for the most accurate and up-to-date information regarding dietary supplement manufacturing dates and labeling requirements.