Understanding the World of OEM Manufacturing (Expanded Version)

For entrepreneurs, start-ups, and established companies aiming to enter or expand within the rapidly growing health and wellness market, gaining a deep understanding of OEM supplement manufacturing is a crucial first step. OEM, or Original Equipment Manufacturer, refers to a business model where a specialized company designs, formulates, and manufactures products or components that are subsequently branded and marketed by another company. This approach enables brands to bring high-quality dietary supplements, functional foods, or nutraceuticals to market efficiently, without the extensive capital investment, operational complexity, and regulatory burden involved in building and managing their own production facilities.

OEM partnerships are more than transactional arrangements—they represent strategic collaborations that allow brands to leverage the expertise, advanced technologies, and regulatory compliance capabilities of experienced manufacturers. In today’s competitive nutritional supplement industry, this model provides a critical pathway for innovation, rapid market entry, and scalable growth.

The Strategic Advantages of Partnering with an OEM

Working with an OEM partner provides numerous advantages that can accelerate a brand’s success while reducing operational risks:

1. Access to Specialized Expertise

Established OEM manufacturers possess extensive experience in formulation science, ingredient sourcing, stability testing, regulatory compliance, and large-scale production management. Their R&D teams often include nutritionists, chemists, and quality assurance specialists who ensure that each product not only meets but exceeds industry standards. This deep expertise reduces the learning curve for new brands and mitigates the risk of costly mistakes in areas such as ingredient interactions, dosage optimization, and labeling compliance.

2. Cost Efficiency and Economies of Scale

Manufacturing dietary supplements in-house typically requires significant investment in equipment, production facilities, staff training, and ongoing maintenance. OEM partnerships eliminate these overheads. Manufacturers already have optimized production lines, enabling brands to benefit from economies of scale and lower per-unit costs. These savings can then be reallocated to marketing, distribution, and customer acquisition strategies, allowing companies to maximize ROI without compromising product quality.

3. Speed to Market

Time-to-market is a critical factor in the supplement industry, where trends can evolve rapidly. OEM manufacturers provide ready-to-use stock formulas or fully customized R&D solutions, enabling brands to launch new products faster than traditional in-house production. This agility is particularly valuable for seasonal products, limited editions, or trend-driven formulations such as functional gummies, adaptogen blends, or plant-based protein powders.

4. Regulatory Assurance and Risk Management

Navigating global regulatory frameworks is a complex challenge. Reputable OEM manufacturers ensure compliance with local and international regulations, including FDA (U.S.), EFSA (Europe), and Health Canada standards. They also maintain certifications such as GMP, NSF, USDA Organic, and Non-GMO Project Verified. Partnering with a compliant OEM significantly reduces the risk of product recalls, legal challenges, or market entry delays due to regulatory non-compliance.

Key Considerations for Selecting the Right OEM Partner

Choosing the right OEM partner is critical for long-term brand success. The selection process should carefully evaluate the following aspects:

1. Quality and Safety Standards

Verify the manufacturer’s certifications, quality control procedures, and adherence to Good Manufacturing Practices (GMP). A strong OEM will implement multi-stage testing for raw materials, in-process production, and finished products. They should also conduct third-party laboratory verification for purity, potency, and absence of contaminants such as heavy metals, allergens, or microbial pathogens.

2. Formulation Capabilities

Examine the manufacturer’s ability to produce the dosage forms relevant to your brand, such as capsules, powders, tablets, softgels, gummies, liquid shots, or effervescent tablets. Flexibility in formulation is key if your brand plans to offer both standard and innovative delivery systems.

3. Ingredient Sourcing and Transparency

Reliable OEMs maintain robust supplier networks, sourcing high-quality, traceable, and, where applicable, certified organic ingredients. Transparency in sourcing enhances brand credibility and aligns with increasing consumer demand for clean-label, sustainable, and ethically sourced products.

4. Production Capacity and Scalability

Assess whether the manufacturer can accommodate both small initial production runs and large-scale orders. Flexibility is essential for brands looking to scale globally, expand product lines, or test new formulations without supply chain disruption.

5. Support and Communication

A collaborative OEM partner provides ongoing technical support, regulatory guidance, and timely communication throughout the production lifecycle. Brands should seek partners that offer project management, clear timelines, and proactive problem-solving.

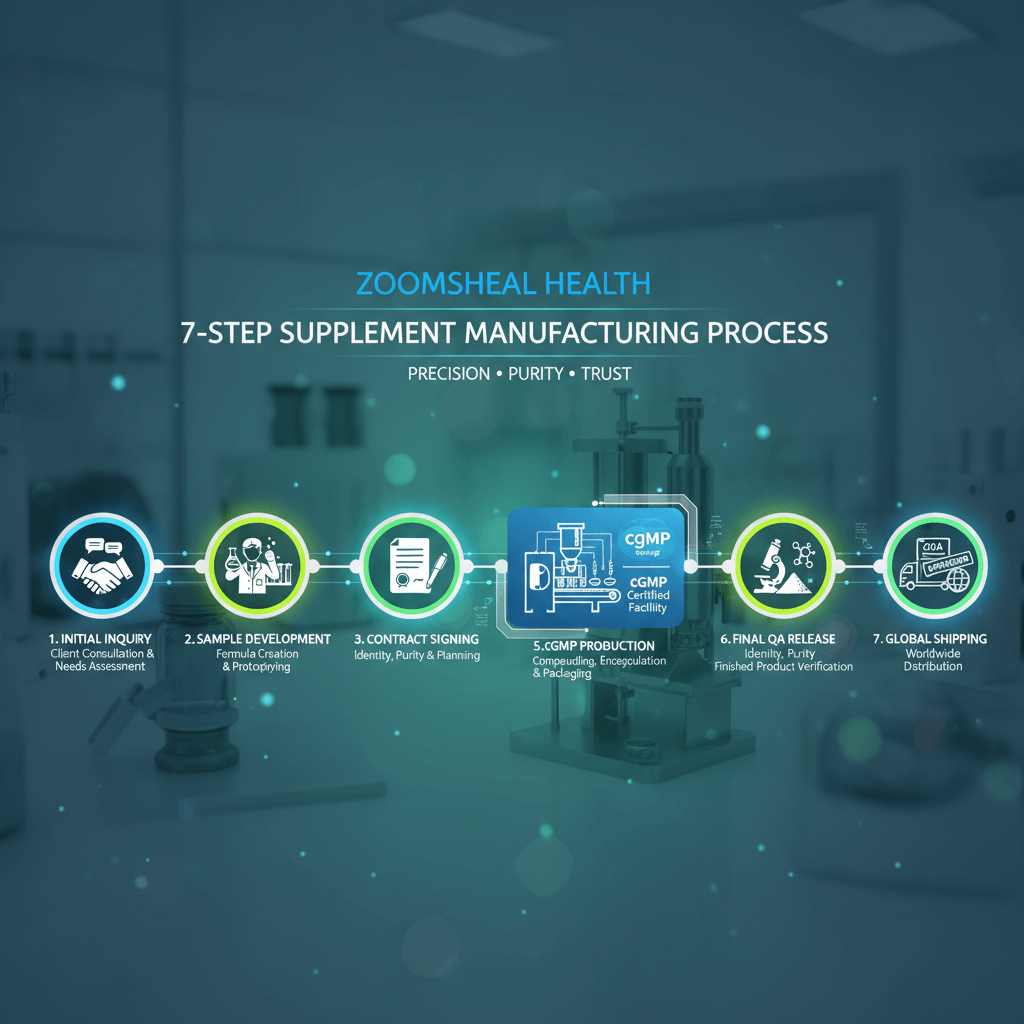

Navigating the OEM Production Journey

The process of bringing a dietary supplement from concept to market through an OEM partnership is a structured and collaborative journey. Understanding each stage can help brands plan effectively, optimize costs, and ensure high-quality outcomes.

1. Initial Consultation and Product Conceptualization

The journey begins with a consultation between your brand team and the OEM. During this phase, you will discuss your product vision, target audience, intended health benefits, desired dosage form, flavor profiles, and packaging preferences. Experienced OEMs often provide guidance based on market trends, scientific evidence, and regulatory considerations to refine your concept. This early collaboration ensures your product idea aligns with both consumer demand and practical production feasibility.

2. Formulation Development

Once the concept is defined, the formulation phase begins. Brands can typically choose between two options:

-

Stock Formulas: Pre-developed, scientifically validated formulas that allow for quick market entry. These are ideal for new brands or those looking to minimize R&D investment while offering proven efficacy.

-

Custom Formulas: Tailored formulations developed in collaboration with the OEM’s R&D team. This path allows for unique ingredient combinations, targeted health benefits, and branded proprietary blends. Custom formulas require more time but differentiate your brand in competitive markets.

During formulation, considerations include ingredient compatibility, dosage optimization, stability, bioavailability, and sensory attributes such as taste, texture, and color. Rigorous in-house testing ensures that the formula performs as intended under various storage and handling conditions.

3. Sample Approval and Iteration

After initial formulation, OEMs produce product samples for evaluation. This stage allows brands to assess taste, texture, visual appeal, and packaging mock-ups. Iterative adjustments can be made to the formula or presentation before entering full-scale production, ensuring alignment with brand expectations and consumer preferences.

4. Regulatory Compliance and Documentation

OEMs assist with the necessary regulatory documentation, including ingredient disclosure, labeling compliance, health claims verification, and certifications. Ensuring all legal requirements are met before production reduces the risk of delays or non-compliance in the target market. Depending on your market, this may involve FDA registration, GRAS status confirmation, or adherence to EFSA guidelines for European markets.

5. Full-Scale Production and Quality Assurance

Upon approval, the product moves into mass production. OEMs employ advanced manufacturing equipment and quality management systems to maintain consistency, safety, and efficacy. Multi-stage quality control includes:

-

Raw material inspection for purity and potency

-

In-process monitoring of formulation, mixing, and encapsulation

-

Final product testing for microbial limits, heavy metals, allergens, and stability

This rigorous oversight ensures that every batch meets both internal and regulatory quality standards, giving brands confidence in the final product’s safety and effectiveness.

6. Packaging, Labeling, and Logistics

The final stage involves professional packaging and labeling tailored to the brand’s specifications. OEMs can provide options ranging from bottles, pouches, blister packs, to eco-friendly and innovative packaging solutions. Once packaged, products are prepared for distribution with comprehensive logistics support, including inventory management, shipping documentation, and global shipping compliance. This turnkey approach allows brands to focus on marketing, sales, and customer engagement while the OEM manages the complex operational aspects of production.

Strategic Advantages of Long-Term OEM Partnerships

Working with an OEM partner is not just a short-term production solution—it can become a cornerstone of your brand’s long-term strategy. Understanding these advantages helps brands maximize the value of the partnership beyond simple manufacturing.

1. Accelerated Time-to-Market

By leveraging the expertise, facilities, and pre-existing processes of an experienced OEM, brands can significantly reduce the lead time from concept to market-ready product. This agility allows companies to respond quickly to emerging health trends, seasonal demands, and competitive pressures, securing a first-mover advantage in fast-paced wellness markets.

2. Access to Specialized Knowledge and Innovation

Top-tier OEMs employ teams of formulation scientists, quality assurance specialists, regulatory experts, and process engineers. This deep reservoir of knowledge enables brands to:

-

Integrate cutting-edge ingredients and functional blends

-

Develop novel dosage forms, such as gummies, effervescent tablets, or liquid shots

-

Utilize advanced encapsulation or bioavailability technologies

-

Ensure formulations meet regulatory and safety standards worldwide

Such access to innovation often surpasses what a brand could achieve independently without substantial R&D investment.

3. Cost Efficiency and Resource Optimization

Partnering with an OEM eliminates the need for significant capital expenditures on facilities, equipment, and staff. Brands benefit from the manufacturer’s economies of scale, purchasing power, and operational efficiency. This cost advantage can be strategically reinvested into marketing, consumer education, or global expansion initiatives, accelerating business growth without overextending resources.

4. Flexibility in Product Scaling and Customization

Whether launching a single SKU or a multi-product line, OEMs provide scalability without compromising quality. They can handle variable order quantities, seasonal spikes, and large-scale production runs. Additionally, their flexibility in creating customized formulas and packaging allows brands to cater to niche markets or introduce limited-edition products that resonate with consumers.

5. Risk Mitigation and Regulatory Assurance

Navigating the complex landscape of dietary supplement regulations can be challenging. OEM partners mitigate risks through rigorous adherence to GMP standards, third-party certifications, and compliance with local and international regulations. This reduces liability and ensures that products meet market-specific legal requirements, safeguarding brand reputation and consumer trust.

6. Enhancing Brand Reputation Through Consistency and Quality

Consistency is critical in the supplement industry. An OEM partner ensures every batch of your product maintains the same potency, taste, and appearance, reinforcing brand credibility. High-quality products backed by reliable manufacturing build long-term consumer loyalty and positive reviews, directly impacting repeat purchase rates and market share growth.

7. Driving Continuous Innovation

Long-term OEM relationships can foster continuous product innovation. Collaborative research and development efforts allow brands to explore new functional ingredients, reformulate products for improved efficacy, or adapt to emerging health trends. This proactive innovation ensures your brand remains competitive and responsive to evolving consumer demands.

Expanding Your Brand Through OEM Manufacturing and Global Distribution

Partnering with an OEM manufacturer does more than simplify production—it opens doors to global market opportunities and strategic brand growth. Understanding how OEM collaborations influence international expansion and competitive positioning is critical for any health and wellness brand.

1. Simplifying Global Market Entry

Expanding into new regions involves navigating complex regulatory landscapes, ingredient approvals, and packaging requirements. Experienced OEMs often have extensive knowledge of international standards, including FDA, EFSA, Health Canada, TGA (Australia), and other region-specific regulations. By leveraging an OEM’s expertise, brands can avoid costly compliance errors and ensure their products meet local legal requirements from day one.

2. Access to a Wide Range of Dosage Forms and Formats

Different markets and consumer segments have varied preferences—some may favor capsules, while others prefer powders, gummies, or ready-to-drink liquids. A proficient OEM provides versatility in dosage forms, enabling brands to cater to multiple markets simultaneously. This adaptability can enhance global appeal and consumer satisfaction, giving your brand a competitive edge.

3. Streamlined Supply Chain and Logistics

Global distribution requires efficient supply chain management. Many OEMs have established logistics networks and partnerships that facilitate international shipping, storage, and customs compliance. By leveraging these systems, brands can ensure timely delivery, reduce shipping costs, and maintain product integrity across borders, building a reliable reputation among distributors and end consumers alike.

4. Brand Differentiation Through Innovation and Quality

OEM partners often provide access to proprietary ingredients, advanced formulations, and cutting-edge delivery technologies. By incorporating these innovations into your products, your brand can differentiate itself in a crowded market. Whether it’s using clinically proven probiotic strains, unique herbal blends, or high-bioavailability nutrients, OEMs empower brands to offer scientifically-backed and marketable health solutions.

5. Scalability for Rapid Growth

As your brand gains traction, demand can fluctuate or scale quickly. OEMs are equipped to handle increasing production volumes without sacrificing quality. This scalability ensures that your brand can respond to market growth, seasonal demand, and promotional campaigns without production bottlenecks.

6. Strengthening Market Competitiveness

The supplement and wellness industry is highly competitive. OEM partnerships allow brands to focus on marketing, consumer engagement, and brand building while leaving production, compliance, and quality assurance to trusted specialists. This division of expertise ensures faster time-to-market, higher product quality, and better customer experiences—factors that directly improve market share and profitability.

7. Risk Mitigation in Product Development

Launching new products always carries risks, from formulation errors to regulatory challenges. OEMs provide a safety net through rigorous R&D, quality testing, and adherence to global standards. By minimizing these risks, brands can confidently innovate and expand their product lines without exposing themselves to unnecessary financial or reputational losses.

8. Long-Term Strategic Growth

Successful OEM partnerships can evolve into long-term collaborations, where the manufacturer becomes a strategic ally in brand development. Over time, the OEM’s expertise in trends, market demands, and scientific innovations helps brands anticipate shifts in consumer preferences, enabling proactive product launches and sustained competitive advantage.

Expanding Your Brand Through OEM Manufacturing and Global Distribution

Partnering with an OEM manufacturer does more than simplify production—it opens doors to global market opportunities and strategic brand growth. Understanding how OEM collaborations influence international expansion and competitive positioning is critical for any health and wellness brand.

1. Simplifying Global Market Entry

Expanding into new regions involves navigating complex regulatory landscapes, ingredient approvals, and packaging requirements. Experienced OEMs often have extensive knowledge of international standards, including FDA, EFSA, Health Canada, TGA (Australia), and other region-specific regulations. By leveraging an OEM’s expertise, brands can avoid costly compliance errors and ensure their products meet local legal requirements from day one.

2. Access to a Wide Range of Dosage Forms and Formats

Different markets and consumer segments have varied preferences—some may favor capsules, while others prefer powders, gummies, or ready-to-drink liquids. A proficient OEM provides versatility in dosage forms, enabling brands to cater to multiple markets simultaneously. This adaptability can enhance global appeal and consumer satisfaction, giving your brand a competitive edge.

3. Streamlined Supply Chain and Logistics

Global distribution requires efficient supply chain management. Many OEMs have established logistics networks and partnerships that facilitate international shipping, storage, and customs compliance. By leveraging these systems, brands can ensure timely delivery, reduce shipping costs, and maintain product integrity across borders, building a reliable reputation among distributors and end consumers alike.

4. Brand Differentiation Through Innovation and Quality

OEM partners often provide access to proprietary ingredients, advanced formulations, and cutting-edge delivery technologies. By incorporating these innovations into your products, your brand can differentiate itself in a crowded market. Whether it’s using clinically proven probiotic strains, unique herbal blends, or high-bioavailability nutrients, OEMs empower brands to offer scientifically-backed and marketable health solutions.

5. Scalability for Rapid Growth

As your brand gains traction, demand can fluctuate or scale quickly. OEMs are equipped to handle increasing production volumes without sacrificing quality. This scalability ensures that your brand can respond to market growth, seasonal demand, and promotional campaigns without production bottlenecks.

6. Strengthening Market Competitiveness

The supplement and wellness industry is highly competitive. OEM partnerships allow brands to focus on marketing, consumer engagement, and brand building while leaving production, compliance, and quality assurance to trusted specialists. This division of expertise ensures faster time-to-market, higher product quality, and better customer experiences—factors that directly improve market share and profitability.

7. Risk Mitigation in Product Development

Launching new products always carries risks, from formulation errors to regulatory challenges. OEMs provide a safety net through rigorous R&D, quality testing, and adherence to global standards. By minimizing these risks, brands can confidently innovate and expand their product lines without exposing themselves to unnecessary financial or reputational losses.

8. Long-Term Strategic Growth

Successful OEM partnerships can evolve into long-term collaborations, where the manufacturer becomes a strategic ally in brand development. Over time, the OEM’s expertise in trends, market demands, and scientific innovations helps brands anticipate shifts in consumer preferences, enabling proactive product launches and sustained competitive advantage.

How to Choose the Right OEM Partner for Your Supplement Brand

Selecting the right OEM partner is crucial for the long-term success of your dietary supplement line. A strong partnership not only ensures high-quality products but also accelerates market entry and supports brand growth. The following considerations and evaluation criteria can help brands make informed decisions:

1. Manufacturing Expertise and Capabilities

Assess the OEM’s technical capabilities and experience in producing your desired product types. Key questions include:

-

Can the manufacturer produce the dosage forms you require, such as capsules, gummies, powders, softgels, or liquids?

-

Do they have experience with specialized formulations, including probiotics, adaptogens, vitamins, and herbal blends?

-

Are they capable of scaling production to meet both small-batch pilot runs and large-volume orders?

An OEM with broad manufacturing expertise can accommodate growth, product line diversification, and evolving market demands.

2. Regulatory Compliance and Certifications

Regulatory compliance is non-negotiable. A reputable OEM should hold:

-

GMP (Good Manufacturing Practices) Certification: Ensures products are consistently produced and controlled according to quality standards.

-

FDA Registration or Equivalent: Demonstrates adherence to national and international regulations.

-

Additional certifications, such as NSF, ISO, USDA Organic, or Non-GMO Project Verified, can provide extra credibility and appeal to niche consumer segments.

These certifications reduce risk, build consumer trust, and simplify market entry.

3. Quality Control and Assurance Systems

Quality assurance processes are vital for maintaining product safety, efficacy, and consistency. Evaluate whether the OEM implements:

-

In-house and third-party testing for purity, potency, and stability

-

Traceability systems for raw materials and final products

-

Robust documentation procedures to ensure compliance and facilitate audits

A manufacturer that prioritizes quality reduces the likelihood of recalls, regulatory issues, and consumer complaints.

4. Research and Development (R&D) Support

OEMs that provide strong R&D support can help brands innovate. Consider:

-

Do they offer custom formulation services?

-

Can they advise on ingredient selection, dosage optimization, and synergistic blends?

-

Do they conduct stability, sensory, and bioavailability testing?

High-quality R&D capabilities enable brands to differentiate their products, address emerging consumer trends, and maintain scientific credibility.

5. Transparency and Communication

Effective communication is critical. Brands should look for OEMs that:

-

Maintain clear timelines for product development and production

-

Provide transparent pricing and MOQ (minimum order quantity) policies

-

Offer proactive updates during each stage of the manufacturing process

A transparent OEM fosters trust, minimizes misunderstandings, and ensures smooth collaboration from start to finish.

6. Supply Chain Management and Global Reach

If you plan to distribute internationally, consider the OEM’s logistics capabilities:

-

Can they manage international shipping and customs documentation?

-

Do they maintain stable ingredient sourcing to prevent production delays?

-

Are they experienced with multi-market compliance, labeling, and regulatory differences?

An OEM with a robust supply chain ensures timely delivery, reduces disruptions, and enables brands to expand globally with confidence.

7. Reputation and Track Record

Finally, assess the OEM’s industry reputation:

-

Check for testimonials, client case studies, or references

-

Research their history of compliance and product recalls

-

Evaluate their innovation portfolio and partnerships with well-known brands

A proven track record signals reliability and positions your brand for long-term success.

Strategic Partnerships Drive Brand Growth

Partnering with the right OEM is more than a business transaction—it’s a strategic alliance that shapes your brand’s trajectory. From initial concept to final product delivery, a competent OEM provides expertise, regulatory guidance, quality assurance, and operational efficiency. By carefully evaluating capabilities, certifications, R&D support, communication practices, supply chain management, and reputation, brands can ensure that their supplement products meet the highest standards and thrive in a competitive marketplace.

OEM Collaboration Success Stories and Practical Recommendations

Understanding theory is one thing, but seeing real-world applications demonstrates the true power of OEM partnerships in the supplement industry. Many emerging and established brands have leveraged OEM expertise to launch innovative products efficiently, maintain quality standards, and achieve global reach.

1. Case Study: Launching a Custom Probiotic Line

A mid-sized health brand aimed to release a probiotic supplement targeting digestive health and immunity. Partnering with a reputable OEM allowed them to:

-

Access clinically validated strains and patented delivery systems without investing in costly lab facilities

-

Utilize R&D support to develop a unique multi-strain formula optimized for stability and bioavailability

-

Leverage GMP-certified production to ensure regulatory compliance and high-quality output

-

Scale production to meet both initial pilot demand and subsequent international orders

The result was a successful market launch with minimal operational risk and a strong consumer trust foundation.

2. Case Study: Expanding into Functional Gummies

Another wellness brand wanted to diversify its product portfolio with functional gummies for energy, beauty, and immunity. Through an OEM collaboration, they were able to:

-

Choose from existing proven formulas to accelerate time-to-market

-

Customize flavors, colors, and textures to align with brand identity

-

Ensure stability and shelf-life through advanced encapsulation techniques

-

Obtain support for packaging design, labeling, and compliance for multiple markets

This approach allowed the brand to enter a competitive category quickly and cost-effectively while maintaining high-quality standards.

3. Practical Recommendations for Brands Considering OEM Partnerships

Based on these examples, brands can take the following practical steps to maximize the benefits of OEM manufacturing:

a. Define Your Product Vision Early

Clearly outline your target audience, desired health benefits, preferred dosage forms, and unique selling points. A well-articulated vision helps the OEM guide you effectively through formulation and production.

b. Start with Stock Formulas if Appropriate

Many OEMs offer a portfolio of validated stock formulas. These can be an excellent starting point for rapid market entry, especially if you want to test demand before committing to custom formulations.

c. Leverage R&D Expertise

OEMs often have extensive experience in ingredient combinations, stability testing, and sensory optimization. Engaging them early in formulation development can reduce trial-and-error cycles and ensure a high-quality end product.

d. Maintain Clear Communication Channels

Regular updates, milestone tracking, and transparent communication about raw material sourcing, testing protocols, and timelines are crucial for a smooth collaboration.

e. Plan for Compliance and Certification

Discuss all regulatory requirements upfront, including region-specific labeling, health claims, and certifications (e.g., GMP, NSF, USDA Organic). Compliance planning ensures that your products can be marketed globally without delays.

f. Consider Long-Term Scalability

Ensure your OEM partner can accommodate future growth. Whether it’s higher production volumes, new dosage forms, or expanding into international markets, scalability is key to sustaining brand growth.

g. Protect Intellectual Property

When developing custom formulations, safeguard your unique recipes, branding concepts, and proprietary technologies through clear contracts and confidentiality agreements.

Conclusion: Unlocking Growth Through OEM Expertise

OEM manufacturing is more than outsourcing production—it is a strategic partnership that empowers brands to innovate, maintain quality, and compete in a fast-evolving supplement market. From probiotic capsules to functional gummies, the right OEM provides a blend of technical expertise, regulatory guidance, and production efficiency. By carefully selecting a partner and following practical recommendations, brands can minimize risk, accelerate product launch, and deliver supplements that resonate with consumers worldwide.

Future Trends and Strategic Importance of OEM Partnerships

The health and wellness supplement market is evolving rapidly, driven by technological innovation, consumer demand for personalized nutrition, and increasing regulatory scrutiny. For brands, understanding emerging trends and aligning with the right OEM partner is critical to maintain competitiveness and long-term growth.

1. Personalization and Niche Formulations

Consumer demand is shifting from generic supplements to personalized solutions targeting specific health needs—such as gut health, cognitive function, beauty-from-within, and sports nutrition. OEM manufacturers equipped with advanced R&D capabilities can help brands develop niche formulations that address these specialized demands. By leveraging scientific expertise, brands can introduce targeted products with clinical backing, differentiating themselves in a crowded market.

2. Innovation in Dosage Forms and Delivery Systems

Traditional capsules and tablets are no longer the only options. The rise of gummy supplements, effervescent powders, liquid shots, and microencapsulated ingredients reflects the growing focus on convenience, taste, and bioavailability. OEM partners often possess the specialized technology and production knowledge needed to create stable, high-quality supplements in diverse dosage forms. This flexibility enables brands to meet evolving consumer preferences and deliver an enhanced user experience.

3. Sustainability and Ethical Manufacturing

Modern consumers are increasingly conscious of environmental and ethical factors when purchasing health products. OEM manufacturers that prioritize sustainable sourcing, eco-friendly packaging, and energy-efficient production practices allow brands to align with these values. Brands can leverage OEM capabilities to showcase their commitment to sustainability, boosting brand image and consumer trust.

4. Regulatory Complexity and Global Market Expansion

With supplements being sold internationally, regulatory compliance becomes more complex. OEM partners with global experience can navigate different markets, ensuring products meet local standards for labeling, ingredient safety, and health claims. This support reduces legal risk and accelerates entry into multiple regions, helping brands scale globally without operational hurdles.

5. Strategic R&D Collaborations

OEMs with robust research departments offer more than manufacturing—they provide strategic insights that can guide product innovation. Collaborating closely with R&D teams allows brands to explore new ingredient combinations, validate health claims scientifically, and develop formulations optimized for efficacy, stability, and consumer appeal. This partnership transforms OEM manufacturing into a co-creative process, rather than a simple production arrangement.

6. Risk Mitigation and Business Agility

Partnering with an experienced OEM reduces the operational risks associated with manufacturing, such as equipment failure, supply chain disruptions, or regulatory non-compliance. Brands can focus on marketing, sales, and customer engagement while the OEM ensures high-quality production. This division of expertise creates business agility, allowing brands to respond quickly to market trends and consumer feedback.

7. Long-Term Brand Growth and Innovation Pipeline

OEM partnerships can support a brand’s innovation pipeline by providing continuous access to new ingredients, technologies, and formulation insights. This long-term collaboration enables iterative product development, faster prototyping, and efficient scaling, ensuring the brand remains competitive and innovative over time.

OEM Partnerships as a Strategic Advantage

OEM manufacturing is no longer a mere operational convenience—it is a strategic tool that empowers supplement brands to innovate, scale, and compete globally. By aligning with a knowledgeable OEM partner, brands can access advanced R&D, diverse dosage forms, regulatory expertise, and sustainable manufacturing practices. This collaboration minimizes risk, accelerates product development, and maximizes market potential. In a fast-moving health and wellness industry, the right OEM partnership is a cornerstone of long-term success, enabling brands to deliver high-quality supplements that meet consumer expectations and achieve sustainable growth.